Green Energy Initiatives and Efficient Manufacturing Practices #

Living Fountain is dedicated to advancing sustainable production, aligning our operations with the 12th Sustainable Development Goal (SDG) — ensuring responsible consumption and production patterns. Our approach integrates green sustainability into every aspect of our business planning, with a strong focus on green energy, energy efficiency, and carbon reduction.

Renewable Energy Commitment #

To support clean energy generation, Living Fountain has installed a solar power generation system with a capacity of 97.905 kilowatts. This initiative has made a significant impact:

- In 2021, our solar panels generated 123,419 kWh of renewable energy, resulting in a reduction of 62,820 kilograms of carbon emissions.

- In 2020, the system produced 126,454 kWh, leading to a decrease of 63,480 kilograms of carbon emissions.

Advancing Energy Efficiency in Production #

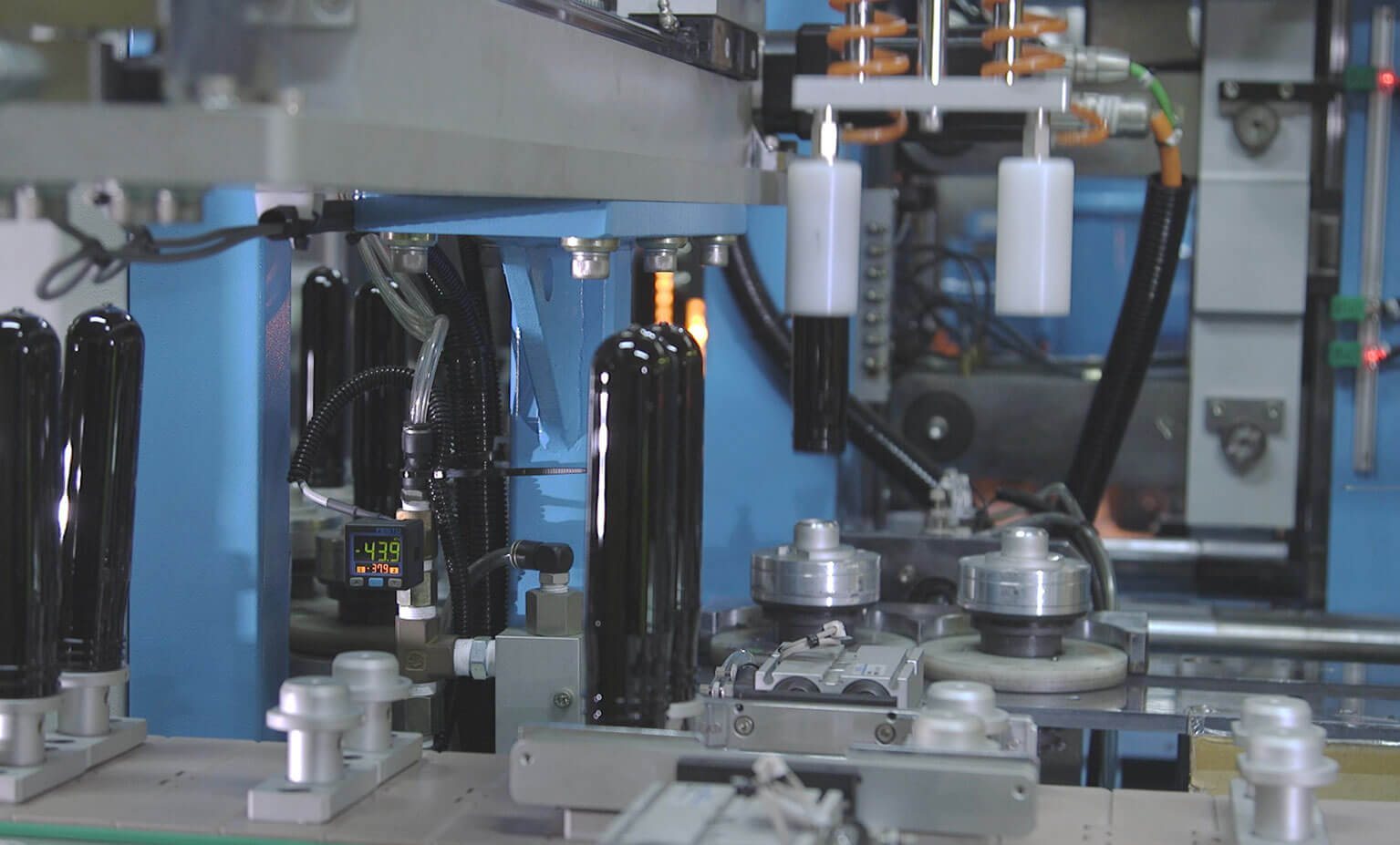

Traditional hydraulic injection molding machines, powered by commercial electricity (220V / 60Hz) and three-phase induction motors, consume substantial energy due to continuous operation and the use of relief valves. To address this, we have transitioned to fully electric injection molding machines, which offer the following benefits:

- Increased production capacity

- Reduced power consumption to just 43.5% of the original, achieving a 56.5% energy saving

Since 2015, we have been systematically replacing traditional machines. By 2020, a total of 11 machines had been upgraded to fully electric models.

Optimizing Equipment for Further Savings #

We have also improved the energy efficiency of our bottle-blowing operations. By adjusting the position of the light tubes in 14 bottle-blowing machines, we achieved approximately 13.7% energy savings.

Through these ongoing efforts, Living Fountain continues to move forward on the path of sustainable production, integrating environmental responsibility into our core manufacturing processes.